What is cataphoresis?

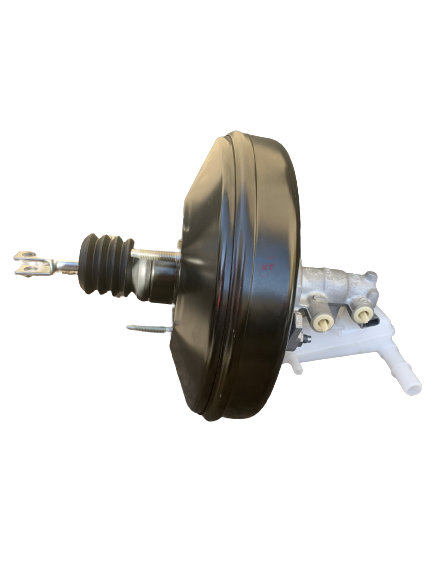

Cathodic electrodeposition or cataphoresis is an immersion painting process, fully automated and based on the displacement of charged particles within an electric field (paint) towards the pole of opposite sign (metal part to be painted). The main objective of the treatment is the protection of surfaces against corrosion, a field in which its properties make it the ideal treatment for this purpose. This treatment allows the painting of areas that are difficult to access such as hollow areas, pipes, etc.

efore applying the paint, the parts go through a surface preparation process consisting of degreasing, tricationic phosphating and different washes. After the application of the paint, the part is subjected to temperature to achieve its polymerization.